MITSUBISHI TABI CO., LTD.

|

||

|

Cultivated tradition and techniques

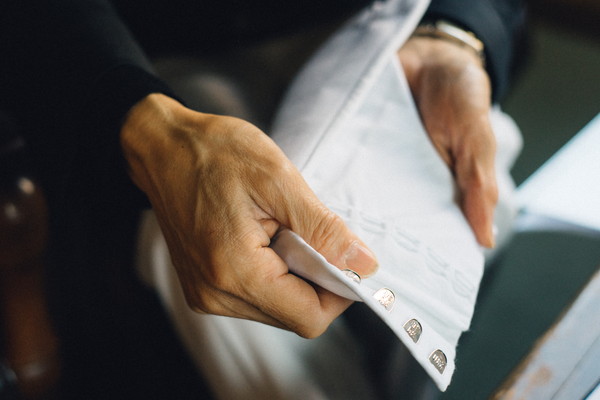

The tabi of JOTARO SAITO, who proposes kimonos as fashion, freely use designs such as camouflage and lace, and gives a sense of glamour that renews the image of traditional tabi. Mitsubishi Tabi has been in charge of the production of these original tabi from JOTARO SAITO for 13 years.

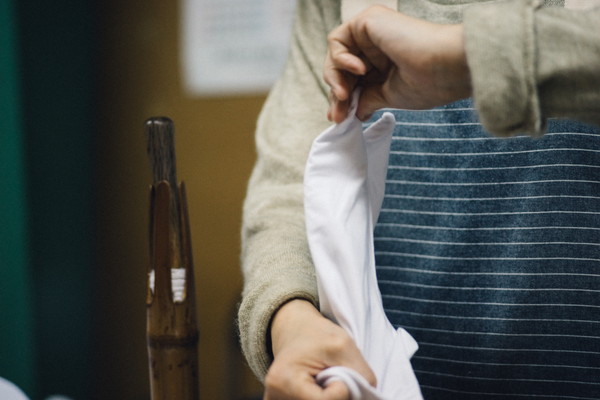

Backed by the motto of “Making the best product in the world at the fastest speed in the world,” skilled craftsmen in the Mitsubishi Tabi factory work the sewing machine pedals little by little, hardly lifting their feet for a break. There are a total of 60 sewing machines specialized for tabi in the company’s factory, creating a pleasant sound of sewing.

Although sewing the tabi might seem simple at first glance, the process is actually divided into 13 steps. “We spare no effort in processes that may be omitted in other companies, such as adding an additional round of stitches in order to increase durability.

We are in pursuit of comfortable and beautiful products with a commitment to each and every step of the process.” says Mr. Hirose, reflecting the manufacturing spirit of Mitsubishi Tabi that has remained unchanged since its founding.

Despite boasting a production volume of approximately 600,000 pairs of tabi per year, Mitsubishi Tabi allows for orders of tabi with an original form and design from just a single pair. In-house pattern makers will manually create and cut the stencil patterns. Traditions have been passed down ceaselessly, always being cherished and put before efficiency.

The appearance of young craftsmen in the factory who bear these techniques can often be seen. While protecting tradition, Mitsubishi Tabi has also been developing new products, such as tabi that use the industry’s first stretchable water repellent material.

“There aren’t many tabi sewing factories that meet production with new materials every season. We are requesting difficult materials this time as well.” says Mr. Jotaro Saito. A kimono style that attracts attention from around the world will be created through the fusion of Mitsubishi Tabi and JOTARO SAITO this season as well.

Interview&Text:Shinya Miyaura (Secori Gallery)

Photography:Yohey Goto

MITSUBISHI TABI Co., Ltd.

Naruto City, Tokushima Prefecture / Established in 1955 / Scope of business: Manufacturing of cotton, various synthetic tabi socks, Sales / No. of employees: 40 persons